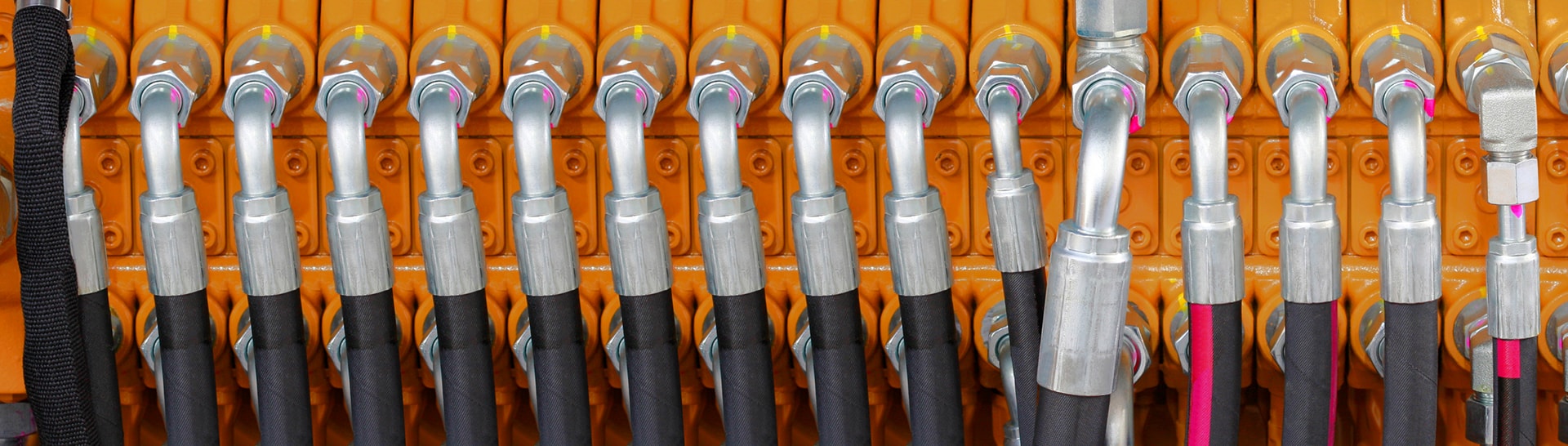

Kent Rubber Supply is a leading source of hydraulic hose, die cut gaskets, hose couplers, and other fluid-conveying products. With the ability to produce a wide range of custom rubber products, you can be confident that our team can produce the hose, fittings, couplers, gaskets, and seals that you need to meet your specific requirements. Below, you will find a brief overview of our capabilities and the services that we offer.

Supply Chain Efficiency Program

KRS is your one-stop source for optimizing supply chain performance. Our products are designed to meet OEMs’ demands for competitiveness, quality, and on-time delivery. We efficiently manage multiple SKUs, ensuring they are stocked, ready for delivery based on production needs, and packed or kitted to minimize shipping costs.

With a strong network of global and domestic partnerships, along with extensive in-house capabilities, we provide the highest quality products at the most competitive prices—ensuring efficiency and reliability in your supply chain.

Gaskets and Seals

Kent Rubber Supply produces custom rubber gaskets and seals with a focus on the high-precision, cost-efficient production of all types of rubber, sponge, foam, Teflon, non-asbestos, and urethane. The majority of our production is focused on die cut gaskets and seals or gaskets and seals cut using our automated flash cut machine, which allows us to cut with maximum precision – for both standard and intricate designs – whether you need two or two thousand pieces.

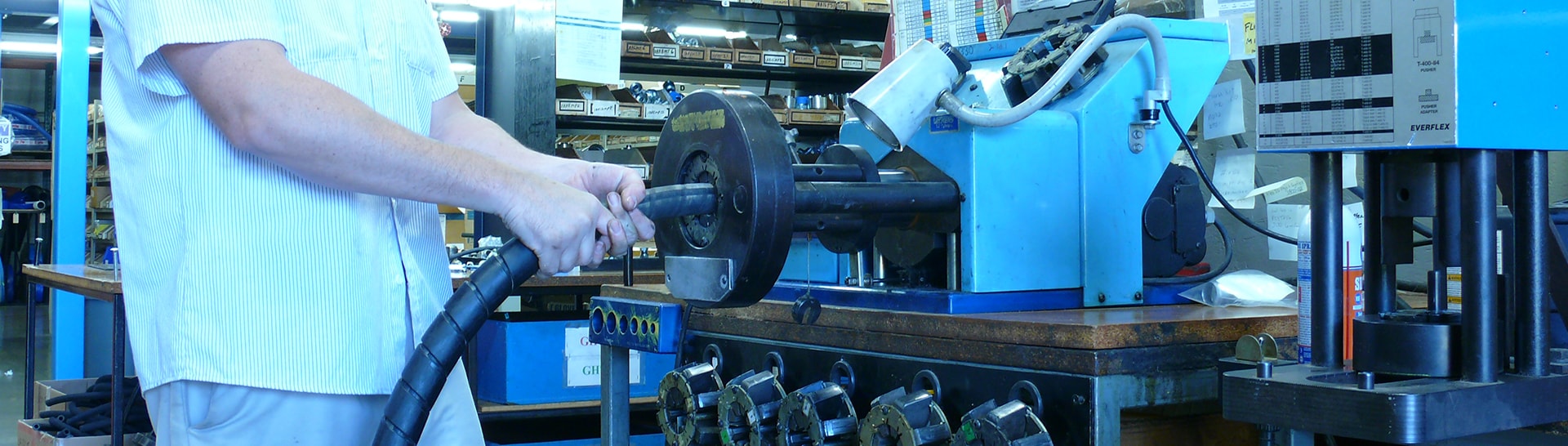

Hose Testing

Whether you are producing a single assembly or a production run, Kent Rubber has the test equipment and hose test specialists to give both you and the end user the assurance that the product has been assembled correctly. We can proof or burst test to a maximum pressure of 21,750 PSI. In addition a programmable PLC Controller gives our operators the ability to pre-program and repeat a test sequence and print the results on the attached tape (optional save to USB).

Automatic Shape Acquisition System

The IntelliScanner Shape Acquisition System is a groundbreaking camera digitization device that seamlessly captures geometric data from cardboard models, paper patterns, and pre-cut components—such as gaskets—without relying on slow mouse pointers or traditional graphic digitizing tablets.

With automated tracing and built-in optical distortion correction, the IntelliScanner exports precise geometry in ATOM format for direct cutting on an ATOM dieless knife cutting system or in DXF format for easy integration into any CAD software.

Simply place single or multiple pre-cut shapes onto the working table, and the system will automatically detect contours, notches, and irregular or uniform holes. It can also define and modify cutting entities such as internal cuts, markings, text, holes with specified diameters, and designated quality zones—enhancing accuracy and efficiency in the digitization process.

Custom molded rubber

For over seventy years, Kent Rubber has been dedicated to providing high-quality custom molded rubber products tailored to our customers’ needs. Regardless of the application, end use, or specifications, we deliver precision-engineered custom hoses, bumpers, seals, O-rings, grommets, and extrusions to meet your exact requirements.

PPAP

Offering many forms and levels of PPAPs, from standard dimensional warrants to level 5, Kent Rubber includes multiple testing certifications to confirm the performance of your custom products.

Material Testing and Selection

Kent Rubber Supply provides testing and diagnosis of multiple styles and types of materials, in addition to providing assessments of their applications. Our testing allows for the gauging of sheet materials for gaskets and other rubber applications. We have the ability to test in-stock products, neoprene orders, FDA nitrile, hi-temp silicone, gum rubber, and sponge.

Prototyping

After helping you design your part and selecting the correct material for your application, Kent Rubber can utilize our dieless flash cut machine to produce a prototype for your approval. Eliminating the need for an initial production run, our prototyping services save you money and help to ensure the applicability of your product.

Die Cutting

Starting with your initial drawn concept, we can work to create completed gaskets and seals by using several die cutting presses. Flexible in our manufacturing, we have the ability to produce your gaskets, seals, and custom hose in a wide range of materials.